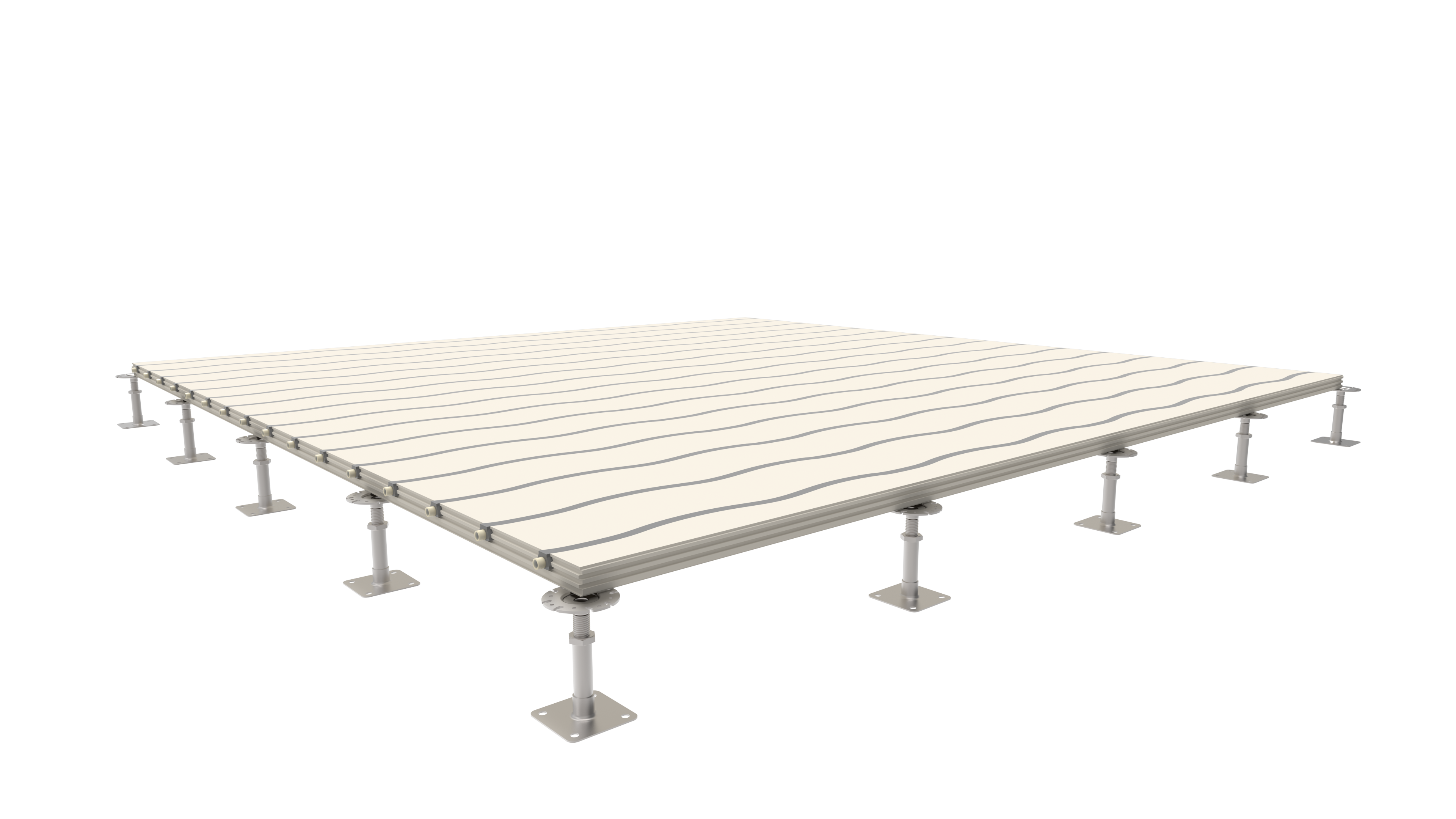

MERO Combi T Thermo

The Combi T Thermo system adds a heating and cooling function to the basic Combi T system. Grooves are milled into the 40 mm thick calcium sulfate boards at the factory to accommodate the 14 mm heating pipes at intervals of either 100 or 150 mm. In order to create a level surface to receive the upper covering and to be able to guarantee the specified heating/cooling capacities, the groove is then filled with mineral. The heating circuit table is usually done by MERO-TSK. The interface to the heating contractor is the existing heating manifold. The pipes pressed by MERO-TSK are laid by the contractor. The system is certified by DIN Certco.

Depending on the laying distance and excess temperature, heating capacities of up to approx. 89 W/m2 and cooling capacities of up to approx. 38 W/m² can be achieved in accordance with DIN EN 1264-2 and -5 respectively.

The load capacity is 3,000 - 5,000 N according to DIN EN 13213.