As functional floors for technics and heavy duty, we designate systems which are mainly used in the field of power supply, data processing, clean rooms and high loads.

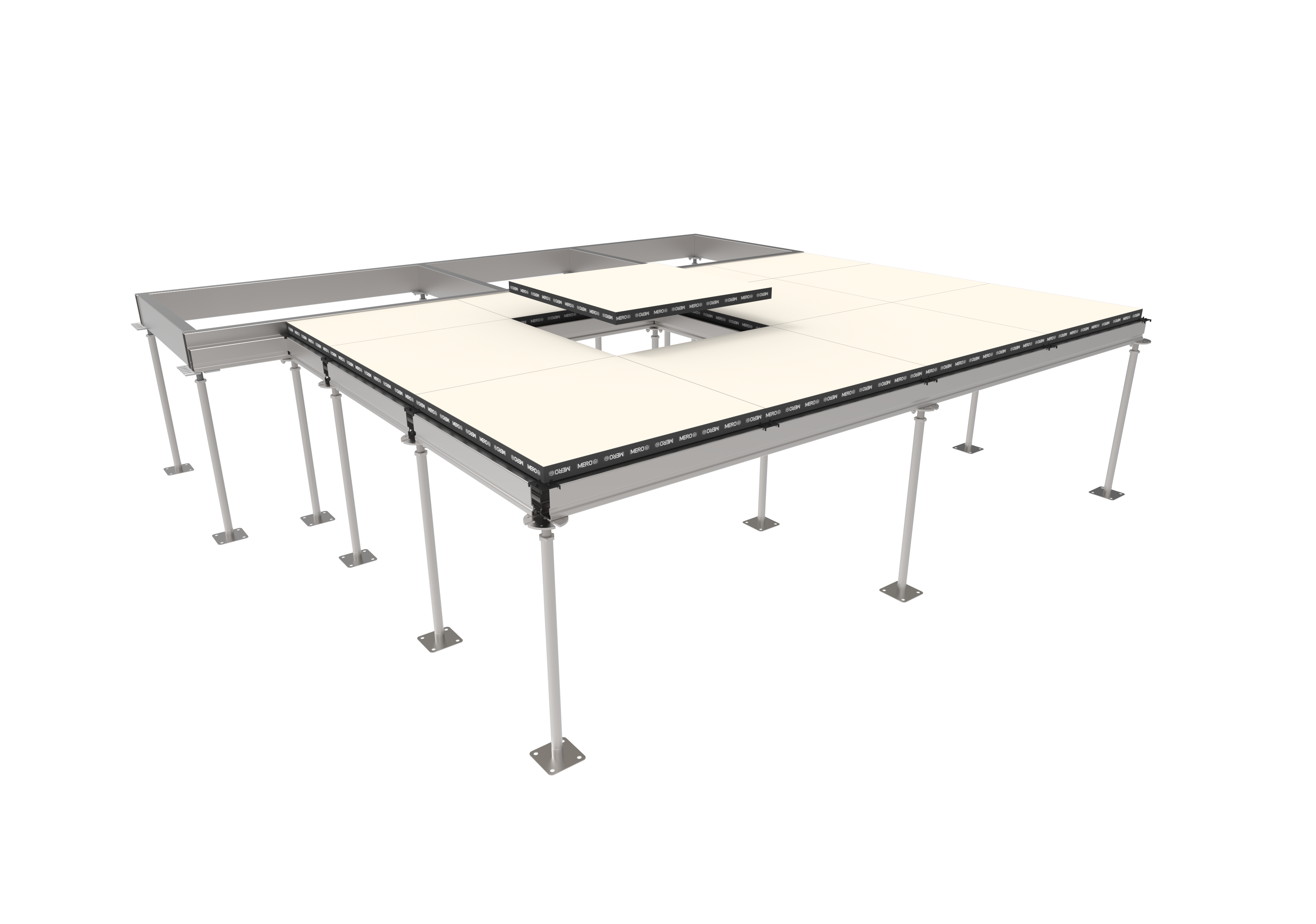

The Type 2 system (the classic control room floor) consists of a self-supporting substructure with C-profiles screwed to the pedestals and a wood-based material (chipboard), calcium sulphate or steel panels lying on top.

The load bearing capacities for the walking area range from 3,000 N to 20,000 N according to DIN EN 12825.

Frame sections can be designed up to a point load of 20,000 N and a line load of 40,000 N.

The Type 3 system consists of powder coated steel panels that rest directly on the pedestal heads gaskets. The material, in combination with matching adhesives and top coverings, provides a high safety level regarding conductivity for ESD areas.

The load bearing capacity of the standard systems ranges up to 6 kN according to DIN EN 12825.

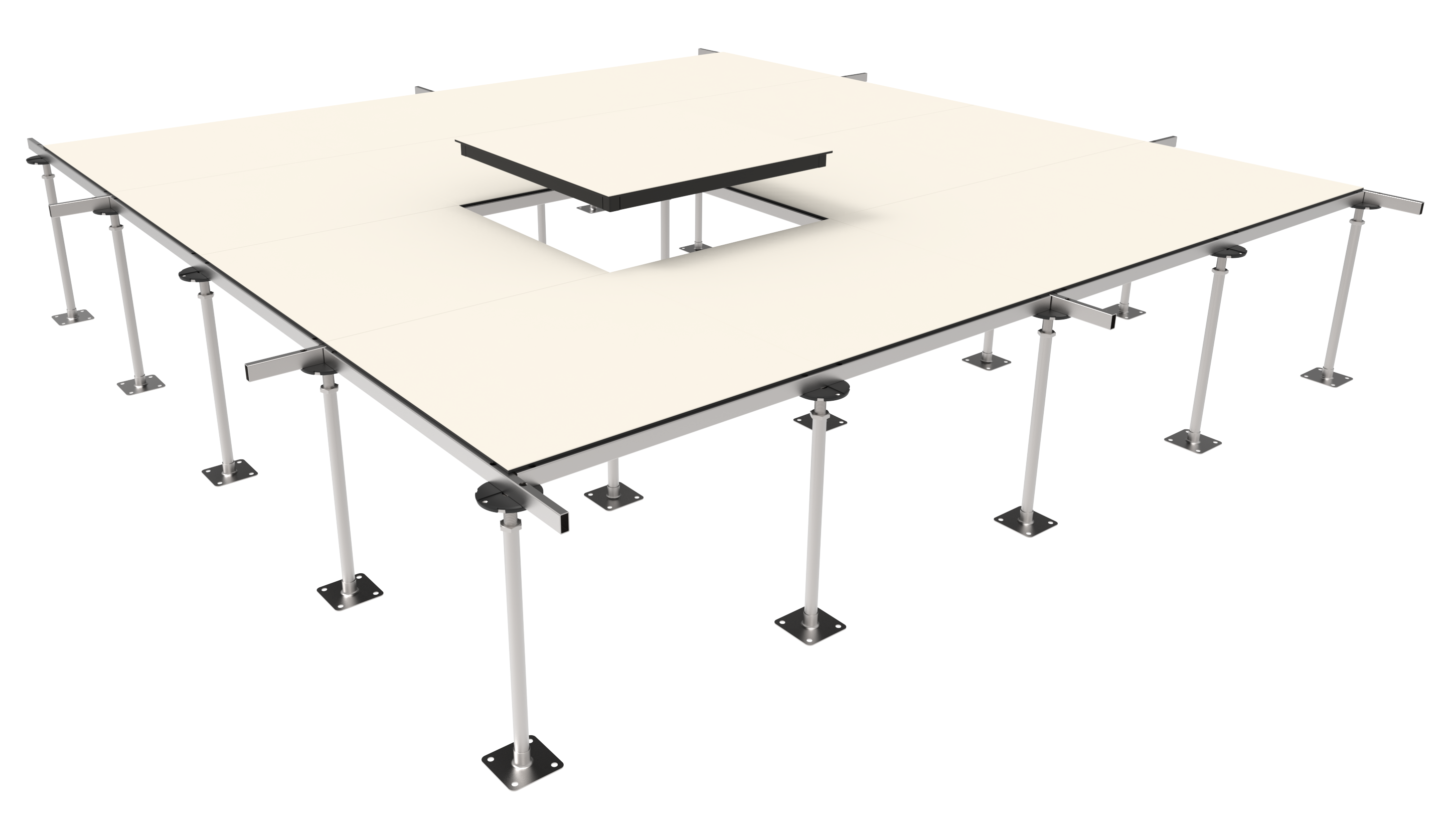

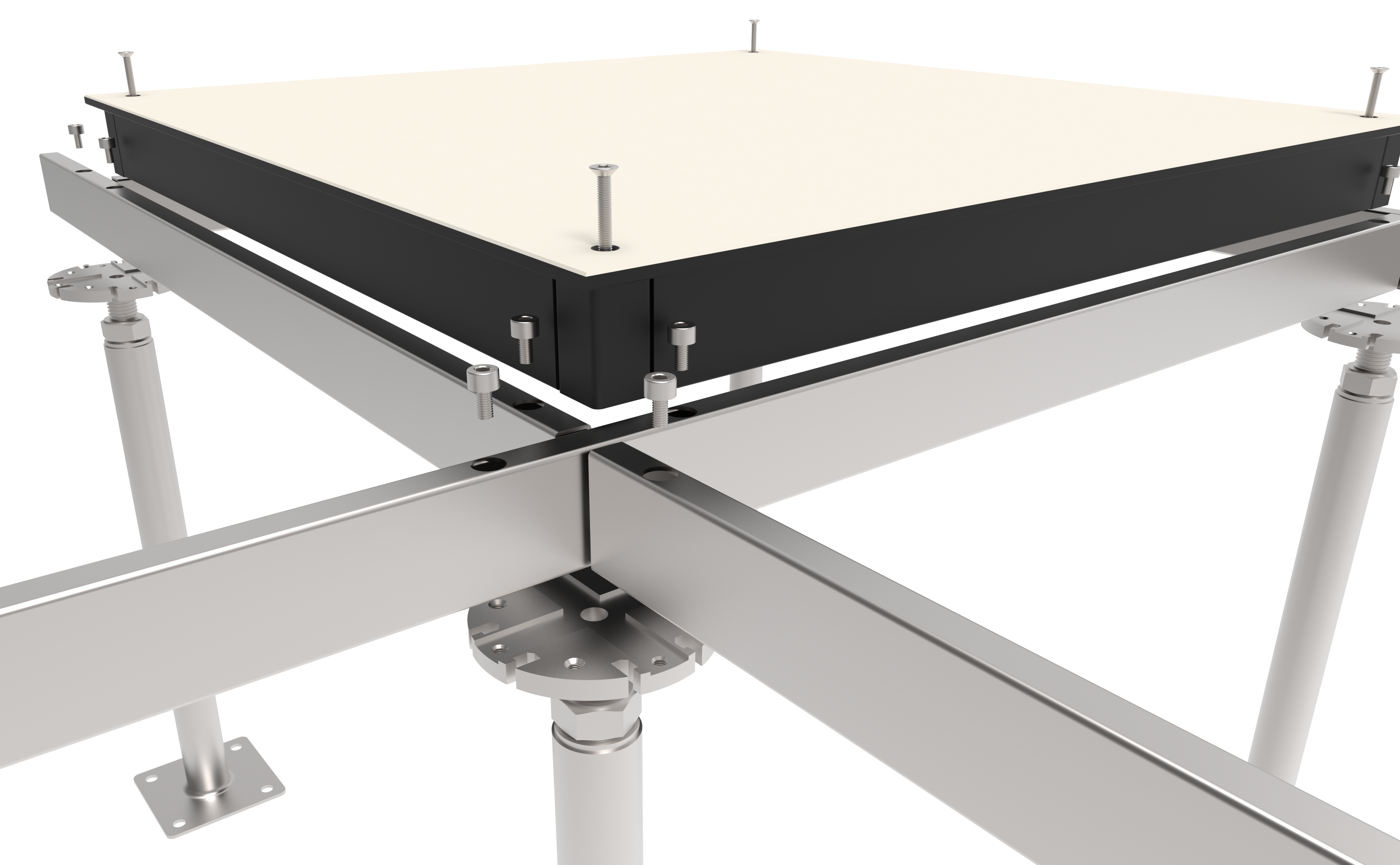

The System Type 3 Dynamic consists of a self-supporting substructure with profiles screwed to the pedestals and interlacing at the panel level. This gives the powder coated steel panels lateral support and transfers shear forces directly into the extremely rigid substructure. From 15 kN on, a standardized panel screwing intensifies this effect.

The load bearing capacities range from 5,000 to 25,000 N according to DIN EN 12825.

Depending on the type a metallic lamination of the underside may be necessary. Possible top coverings range from elastic or textile coverings, to checker plate, parquet or natural stone.