Floor systems

Consulting, project planning, production and assembly - everything from a single source

MERO-TSK is one of the leading system floor manufacturers in Germany and one of the few companies that, in addition to supplying a partner network that has grown over decades in Germany and abroad, also provides its customers with support from a single source, from consultation to acceptance. Our Access Floors and hollow floors can be supplied with integrated underfloor heating/cooling, perforations for ventilation, sound absorption, swelling ventilation and point loads from 2 kN to 25 kN.

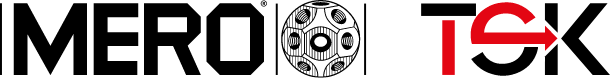

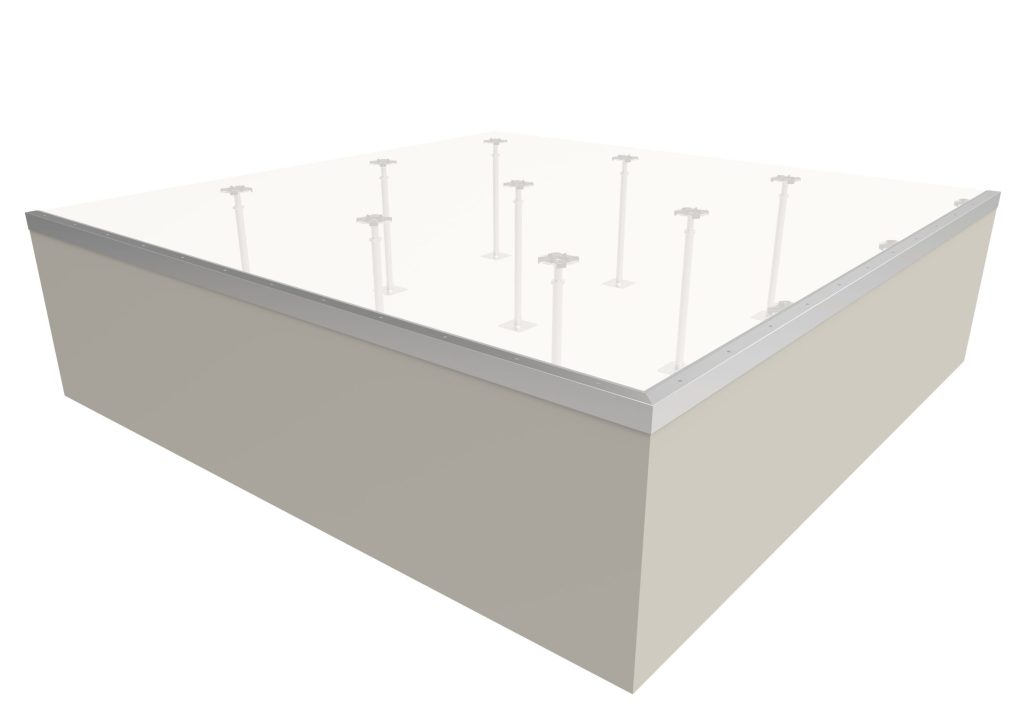

Access Floor

A highly flexible system floor made of engineered wood or gypsum fiber boards, in which all panels can be individually mounted and interchanged.

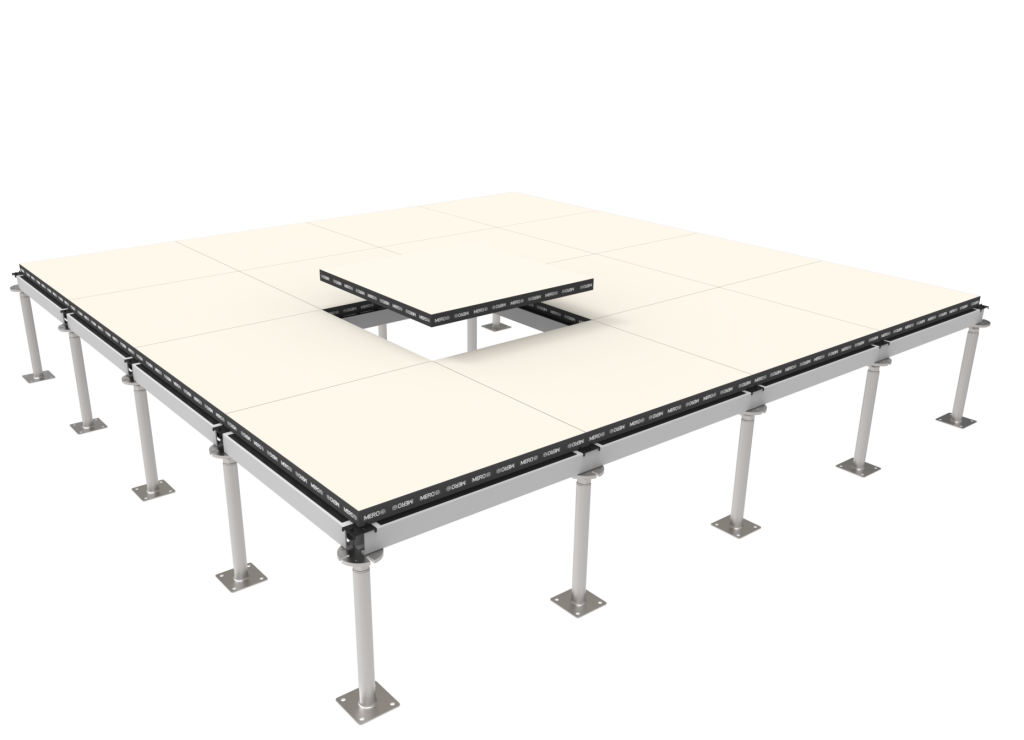

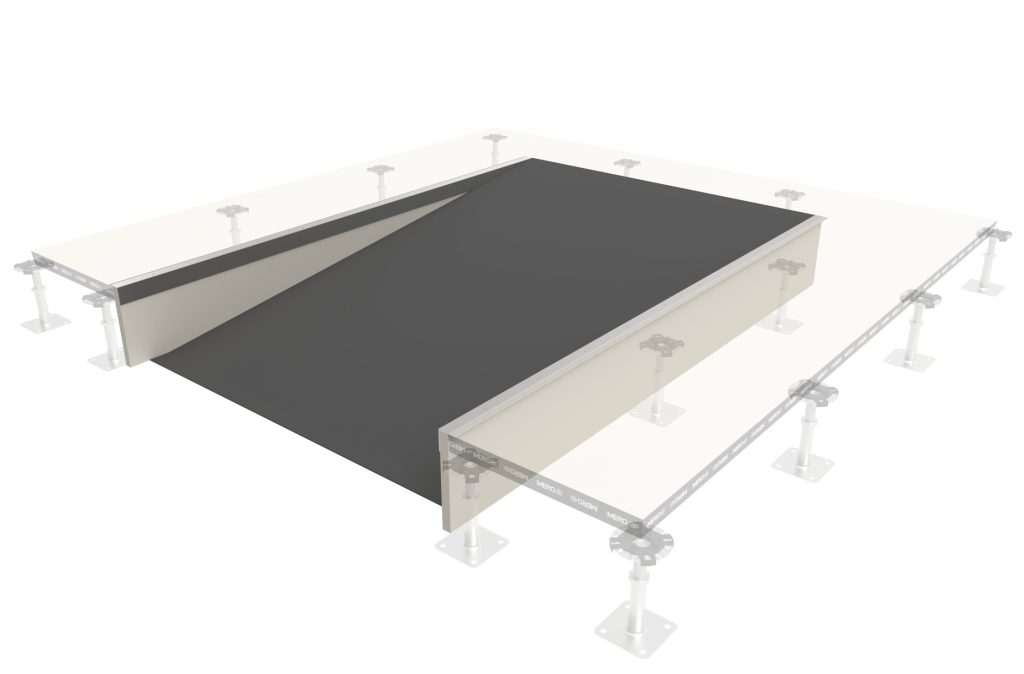

Dry hollow floor

A system floor made of engineered wood or gypsum fiber in which panels are glued together to form a joint-free surface.

Hollow floor wet

A system floor made of anhydrite screed on a lost formwork panel.

References

Contact us

Floor systems

Areas of application

Offices

- Type 5 – Wood-based Access Floor

- Type 6 – Calcium sulphate Access Floor

- Type 6 – Calcium sulphate Access Floor with heating/cooling function

- Type 6 – Calcium sulphate Access Floor with room acoustics/swelling air function

- Combi T – Calcium sulphate

- Combi T – wood-based material

- Combi T – Thermo with heating/cooling function

- Combi T – with room acoustics/ displacement air function

- Combi A – Calcium sulphate tile screed

- Combi A – Thermo with heating/cooling function

Power supply

Clean Rooms

Floor systems

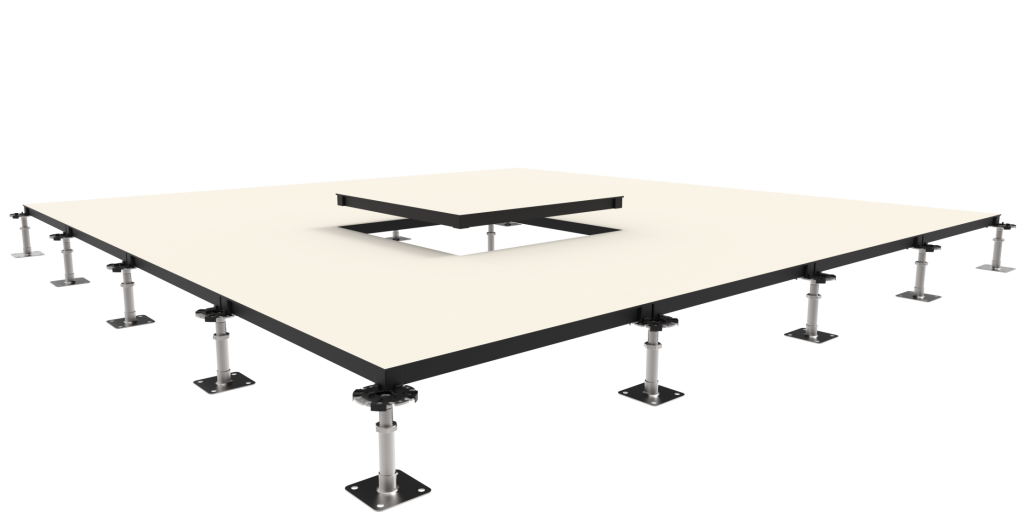

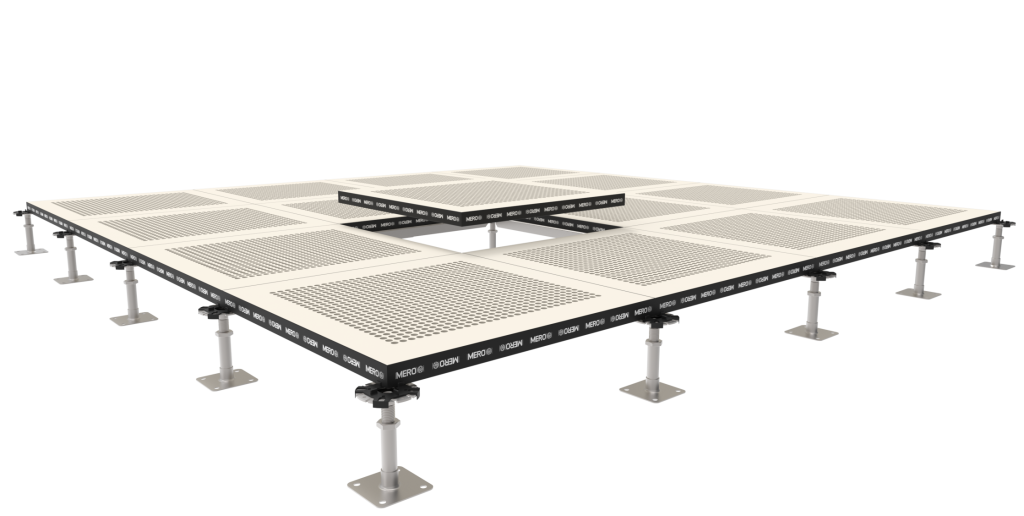

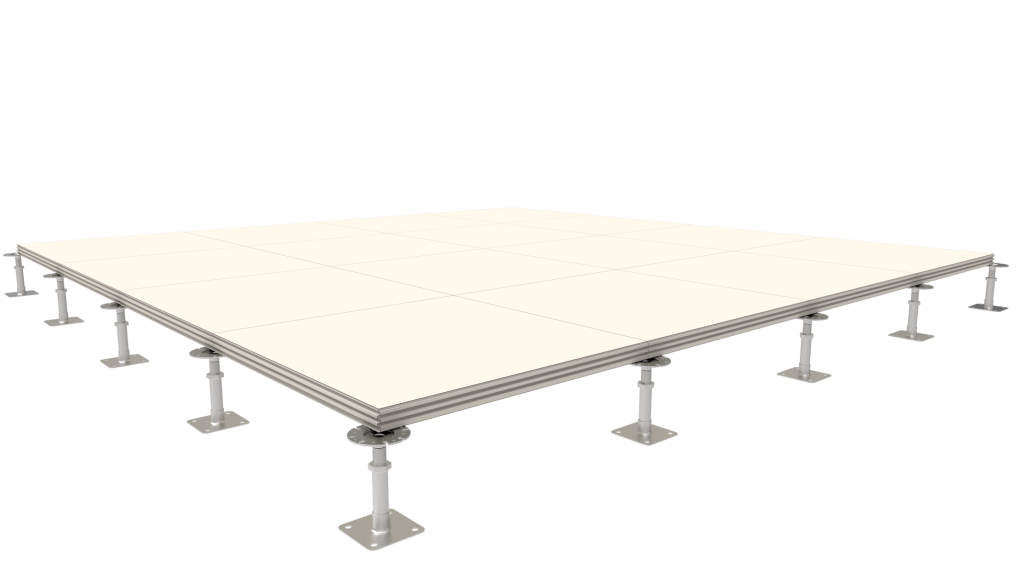

Access Floor

For offices, data centers, power supply, heavy-duty.

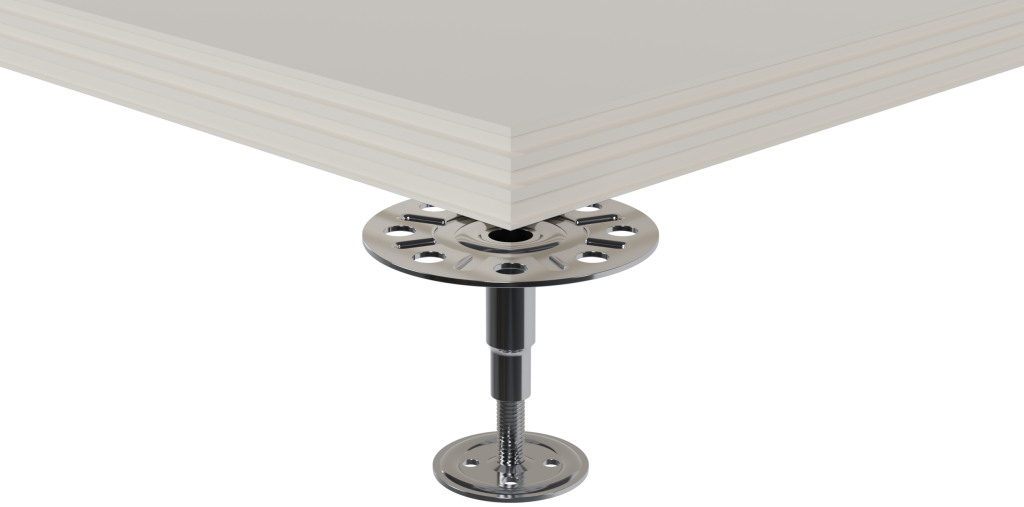

Access Floors offer maximum flexibility among the system floors. The 600 x 600 mm panels can be interchanged as required, e.g. if a workstation is relocated or a ventilation panel is needed at a different location. Our range of Access Floors includes control room systems with point load capacities of up to 20 kN for e.g. data centers and power supply systems, steel Access Floors for clean rooms with high load requirements of up to 25 kN, lightweight systems made of wood-based materials, non-combustible systems e.g. for office areas with additional functions such as displacement ventilation/room acoustics improvement/underfloor heating and cooling. Self-laying carpet tiles or factory-applied textile, elastic, parquet, aluminum corrugated sheet or stone coverings can be used as flooring.

Additional services such as ramps, stairs, railings, equipment inserts, perforated panels with and without volume control, air, sound and fire insulation, etc. complete our product range.

Type 2 - Control room Access Floor

Area of application: mainly in the area of power supply, data processing and high loads

The type 2 Access Floor system (control room system) is mainly used in the power supply and data processing sectors and for heavy-duty applications. In addition to the resilient coverings commonly used in this area, textile coverings, checker plate, parquet or natural stone are also possible for all systems.

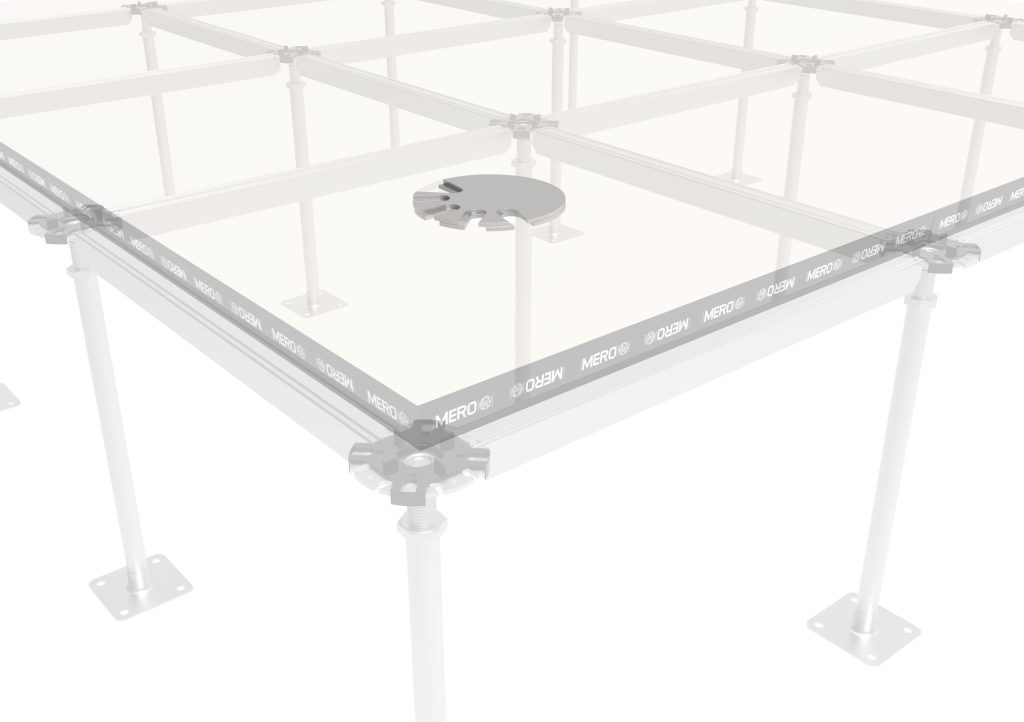

The type 2 system consists of a self-supporting substructure with a grid of 600 x 600 mm, 600 x 1200 mm or 1200 x 1200 mm with C-profiles screwed to the pedestals and a wood-based or calcium sulphate panel on top. Conductive plastic profile supports are used to fix the position.

The load capacities range from 3,000 N to 20,000 N in accordance with DIN EN 12825 for the walking area. The frame areas can be designed up to a point load of 20,000 N and a linear load of 40,000 N.

Type 3 - Steel Access Floor

Area of application: mainly in clean rooms and for high loads

The Type 3 Access Floor system is mainly used in clean rooms and for heavy-duty applications. In addition to the resilient surface coverings commonly used in this area, textile coverings, checker plate or parquet are also possible with all systems.

The Type 3 Classic system consists of powder-coated steel panels that rest on support head pads. In combination with matching adhesives and surface coverings, the material ensures a high level of safety in terms of conductivity in ESD areas.

The maximum point load capacity is 6,000 N in accordance with DIN EN 12825.

The Type 3 Dynamic system consists of a self-supporting substructure with nested profiles bolted to the pedestals at panel level. This gives the powder-coated steel panels lateral support and transfers shear forces directly into the extremely rigid substructure. A standard panel screw connection from 15,000 N reinforces this effect.

The point load capacities range from 5,000 N to 25,000 N in accordance with DIN EN 12825 and its application guidelines.

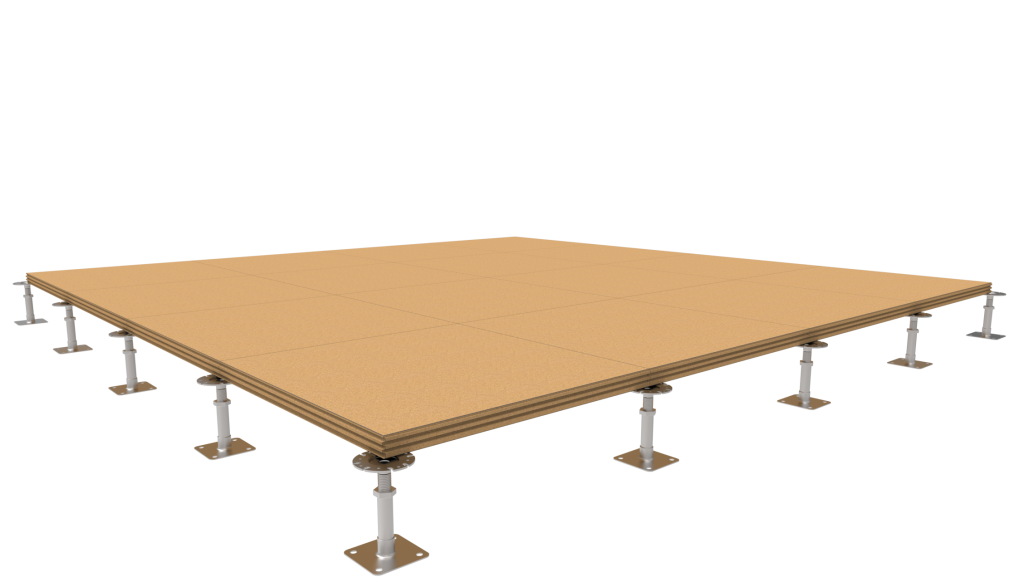

Type 5 - Wood-based Access Floor

Area of application: mainly in offices

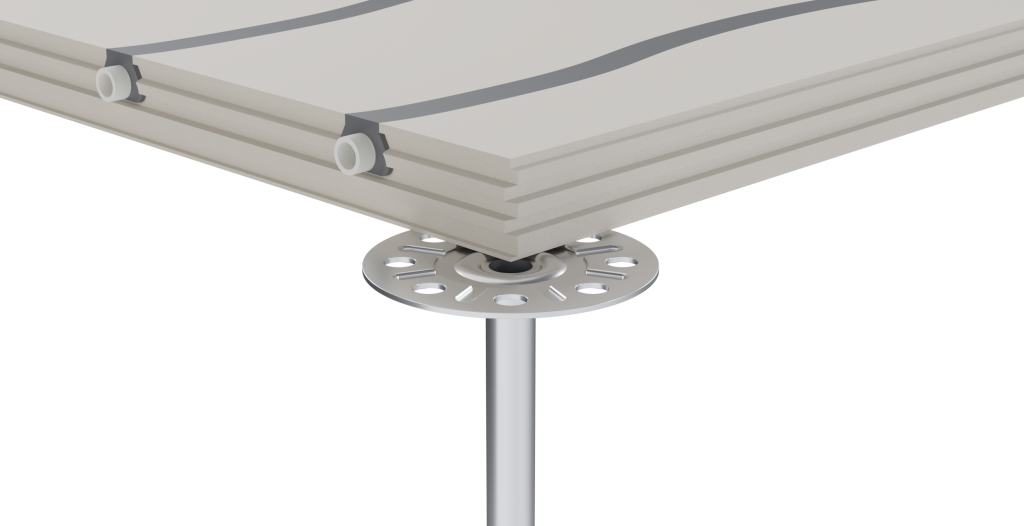

The Type 5 Access Floor system is mainly used in offices. It consists of a base layer with 22 – 38 mm thick wood-based panels, which rest on steel supports in a 600 x 600 mm grid. Conductive plastic support head pads are used to fix the position and provide impact sound insulation. This system offers maximum flexibility, as each panel can be mounted individually. The stringers between the pedestals required for stability or greater load-bearing capacity in higher structures can be easily removed. Depending on the design, metal cladding may be required on the top and/or bottom of the panels. Possible top covering applications are elastic or textile coverings and parquet.

The load capacity is between 2,000 and 5,000N in accordance with DIN EN 12825.

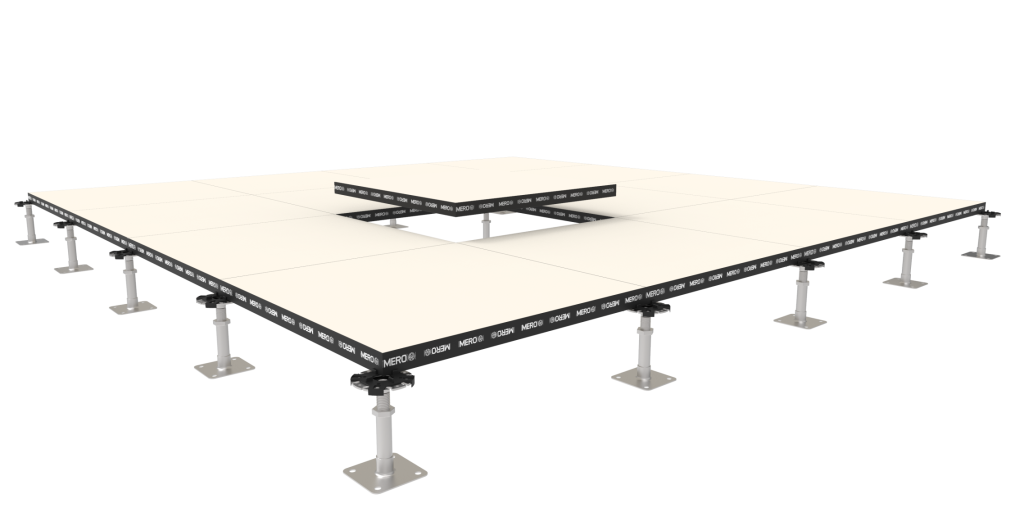

Type 6 - Calcium sulphate Access Floor

Area of application: mainly in offices

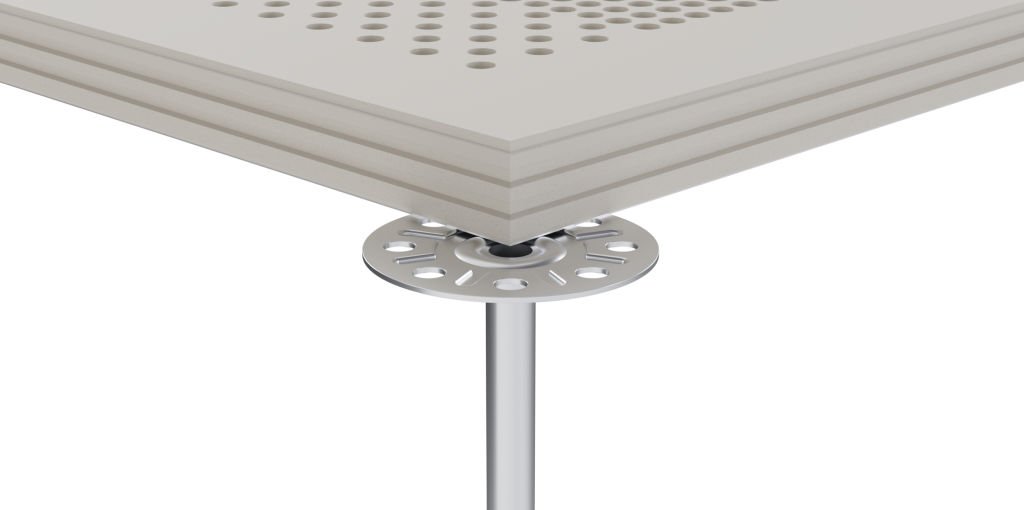

The Type 6 Access Floor system is mainly used in offices. It consists of a base layer with 16 – 40 mm thick calcium sulphate or gypsum fiber boards of building material class A1, which rest on steel supports in a 600 x 600 mm grid. Conductive plastic support head pads are used to fix the layer and provide impact sound insulation. This system offers maximum flexibility, as each panel can be mounted individually. The stringers between the pedestals required for stability or greater load-bearing capacity in higher structures can be easily removed. Depending on the design, metal cladding may be required on the top and/or bottom of the panels. Possible surface covering applications range from elastic or textile coverings to checker plate, parquet or natural stone.

The point load capacity is between 2,000 and 6,000N in accordance with DIN EN 12825.

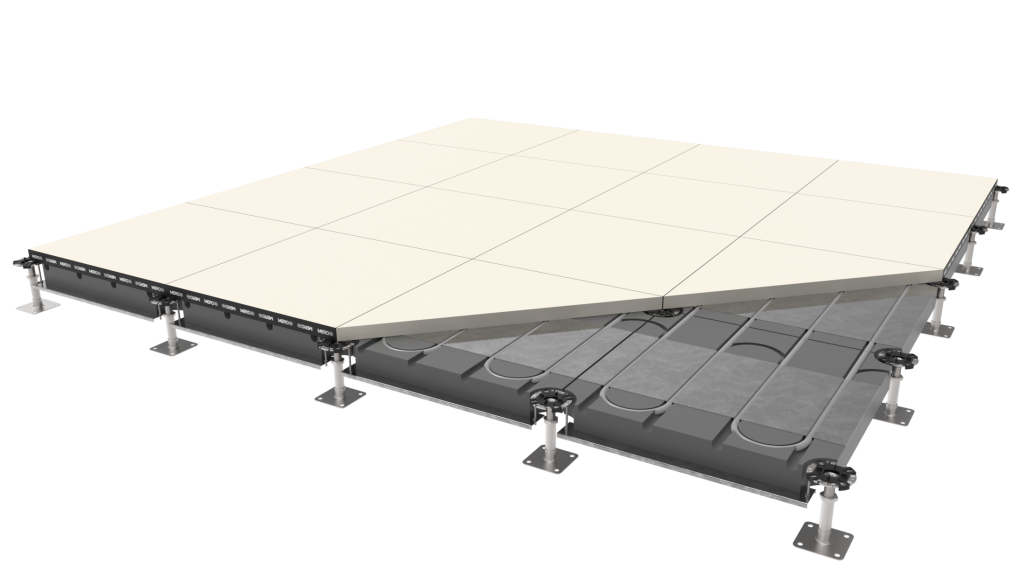

Type 6 Thermo - Calcium sulphate Access Floor with heating/cooling function

The Type 6N36 Thermo Access Floor system adds a heating and cooling function to the basic Type 6 system. Heat conducting plates are embedded in the suspended insulation cassettes to accommodate the Ø14 mm heating pipes. The heating circuit is usually calculated by MERO-TSK. The interface to the heating engineer is the heating circuit manifold provided by the customer. The pipes pressed off by MERO-TSK are installed by the heating engineer. The system is certified by DIN Certco. Possible surface covering applications range from elastic or textile coverings to checker plate, parquet or natural stone.

For subsequent installations, the pipes are pulled out upwards over a length of approx. 2 m so that the insulation cassettes can be removed.

Depending on the flow and return temperatures, heating outputs of up to approx. 91 W/m2 and cooling outputs of up to approx. 23 W/m2 in accordance with DIN EN 1264-2 and -5 can be achieved. The point load capacity is 3,000 N in accordance with DIN EN 12825.

Type 6 Silent/Air - Calcium sulphate Access Floor with room acoustics/swelling air function

The Type 6 Silent/Air Access Floor system combines 2 functions in one system. The perforated calcium sulphate panels absorb sound energy – similar to an acoustic ceiling – especially at low frequencies, thereby reducing reverberation and ensuring pleasant acoustics in the room. With a free cross-section of 10.5% to 26%, for example, with a sheet of Vebe Strong 956 quality needle felt and an acoustic fleece glued to the underside, a weighted sound absorption coefficient αw of 0.50 (LH) to 0.70 (LH) is achieved.

Possible surface covering applications range from elastic or textile coverings to checker plate, parquet or natural stone.

In addition to its acoustic properties, the system can also be used as a displacement air floor. An air flow rate of approx. 28 to 69 m³ per m² and hour is achieved with the above-mentioned choice of cross-section and covering.

With this Access Floor system, the choice of surface covering is limited to self-laying, air-permeable carpet tiles or permanently applied needle felts.

The point load-bearing capacity is 3,000 – 5,000 N according to DIN EN 12825, depending on the free cross-section and load-reinforcing measures.

Floor systems

Access Floor - Accessories

Fire bulkhead

Device use

Stringers

Sound insulation

Brush cable outlet

To avoid unnecessary pressure losses, e.g. in data center operation, our cable outlets are equipped with a two-layer brush arrangement. They are in two parts and can provide a 300 x 200 mm opening for cable entry within a raised floor panel and a 300 x 100 mm opening at the edge of the panel as standard. The side panels are plugged on and therefore allow easy length adjustment on site.

Front cladding

Our front panels serve as a side finish for a free-ending Access Floor. Available in wood-based material or gypsum fiberboard. The step edge is protected by an aluminum bracket. Optionally coated or covered with a top layer.

Railing

Our system plug-in guardrails consist of powder-coated 40 x 40 mm square tubes. The railing can be pulled out of the plug-in shoes anchored to the unfinished floor without the need for tools to insert large equipment.

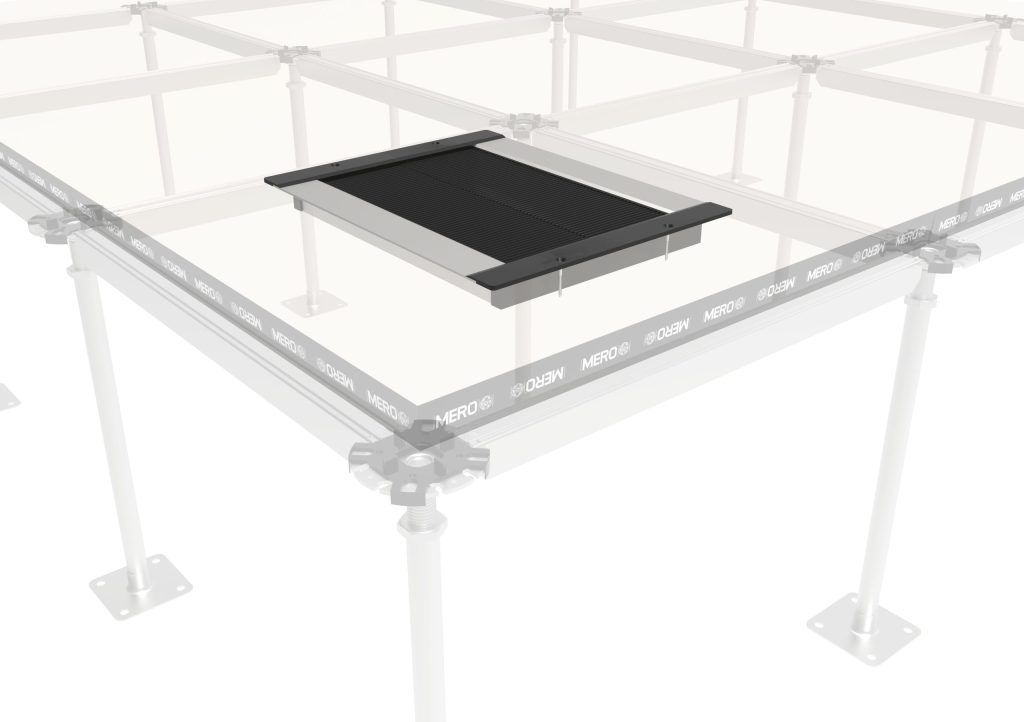

Ventilation panels

Our range of perforated steel panels includes free cross-sections from 24 to 65 %, an air flow rate of up to approx. 2800 m3/h and panel with a pressure loss of 10 Pa. Point load capacities of 3,000 to 10,000 N in accordance with DIN EN 12825 are possible. All perforated steel panels can optionally be equipped with an air volume control that can be conveniently adjusted from above. A lamella construction allows, for example, a continuously adjustable air flow rate of approx. 200 to approx. 2200 m3 / h and panel with a pressure loss of 10 Pa for our 65 % panel.

Ramp

Our ramps are custom-made and can therefore be adapted to any load class. They are fitted with a slip-resistant rubber surface as standard.

Reserve field covers

If enclosure frames are not fitted until a later date, the bays can be covered with raised floor panels. In this case, we optionally offer either a step protection for pedestrian traffic or a version with the nominal load of the adjacent floor.

Enclosure frame

The largest possible free cross-section under an enclosure for cable entry or ventilation can be achieved using frames integrated into the floor. The C-profiles are attached to the support heads with hammer-head bolts. Our type 2 control room system offers a force-fit connection to the walking area. Different frame dimensions can accommodate enclosure weights of up to 20,000 N point load and 40,000 N/m line load.

Heavy-duty cable outlet

Our heavy-duty cable outlet is a stable alternative to the brush cable outlet. The two stainless steel blanks with identically arranged cut-outs can be twisted in opposite directions, allowing maximum minimized passage for cables or a practically airtight seal in the absence of occupancy.

Heavy-duty wall bracket

If a support position in the edge area is not possible, the load can be transferred via wall brackets. The prerequisite for this is a concrete wall design.

Arc fault safety up to 200 mbar

To secure a raised access floor against lifting in the event of an arc fault overpressure in the cavity, the entire construction can be force-fitted to the unfinished floor. Our design includes fixing the base plate with push-through anchors, fixing the threads in the pipe using grub screws or a pipe press and a metric plate screw connection. Cover caps covered with a covering ensure a uniform appearance.

Stairs

Our staircases are individually adapted to the given installation conditions. Available in wood-based material or gypsum fiberboard. The tread edges are protected by an aluminum bracket. The riser is optionally coated or covered with a top layer.

Bridging

If the support position in the standard grid is not possible due to installations or ceiling openings, this area can be supported by bridging. The dimensions of the bridges are individually adapted to the required load and the given installation conditions.

Access Floor - Floor coverings

Depending on the system, possible surface covering applications on our access floor panels range from elastic or textile coverings to checker plate, parquet, or stone. The edging strip is pulled up to the top edge of the covering for elastic coverings (PVC, rubber, linoleum), parquet, natural stone, or porcelain stoneware, thereby protecting the edge of the covering. Textile coverings are only cut to size afterwards in order to achieve a flat appearance.

With resilient coverings, there are hardly any restrictions on the choice of covering. The tile structure is adapted depending on the requirements for site transition, ESD specifications or insulating properties. A variety of textile and stone coverings can also be applied in consultation with us. We offer parquet as strip, mosaic, lamella or English bonded parquet in various arrangements and a large selection of wood types. Surface optionally oiled or lacquered. The edging is color-matched.

Forbo Colorex EC

Forbo Marmoleum Real

Gerflor Marmorette LCH

MERO Classic Special

MERO Elast

MERO Plus

Mipolam Classic

Noraplan Stone ED

Abet HPL Walkprint

MERO HPL lf

MERO HPL nlf

Vebe Strong 956

Parquet flooring

Floor systems

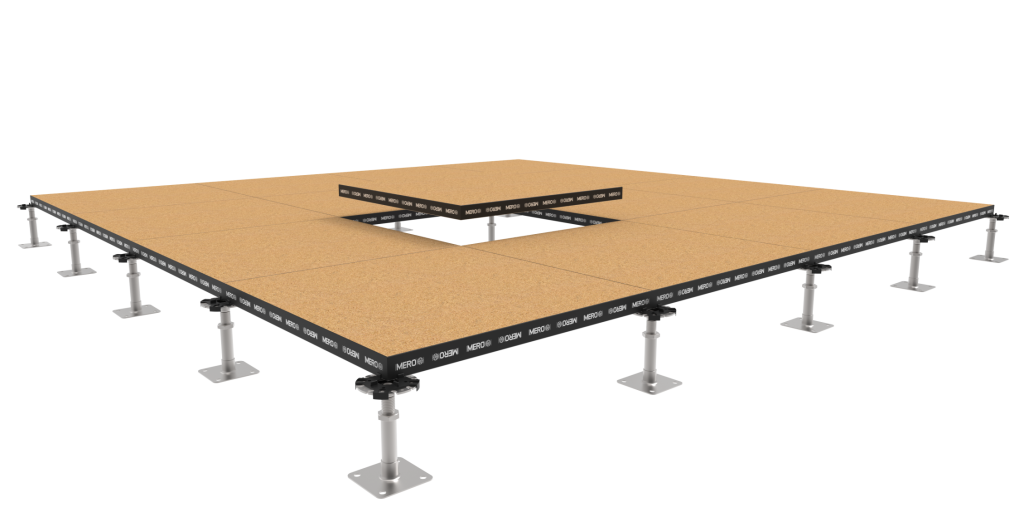

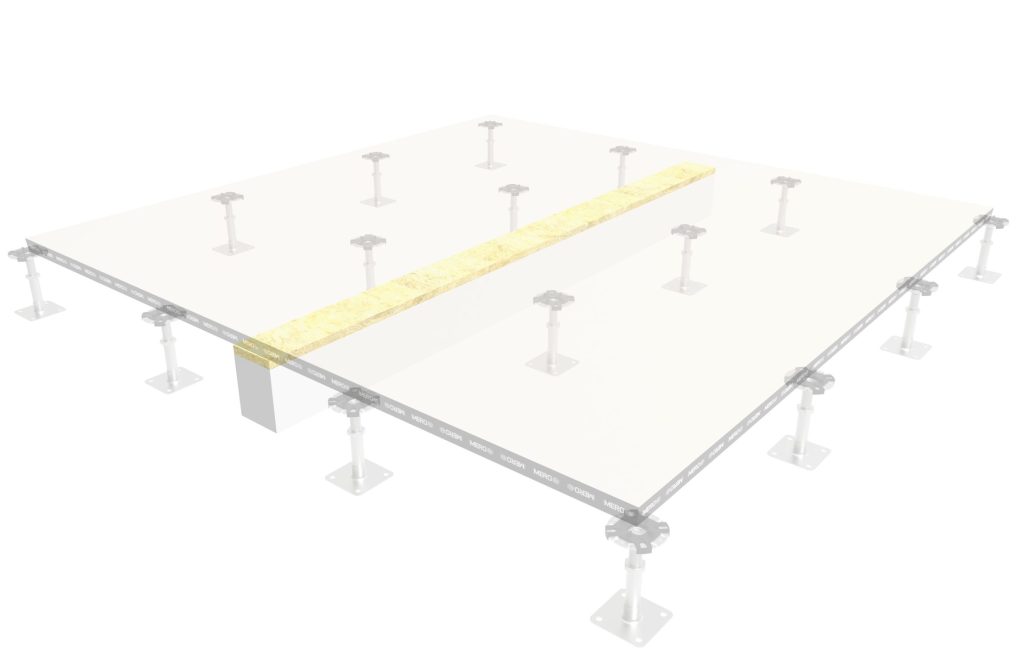

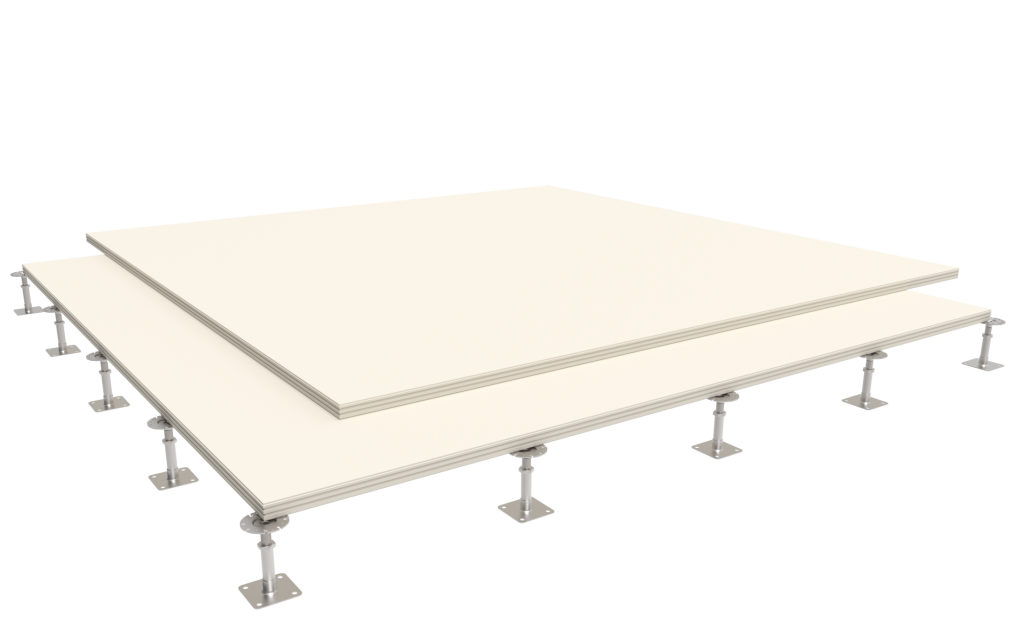

Dry hollow floor

For offices, libraries, laboratories, reception halls, showrooms, heavy-duty areas.

n contrast to screed, dry hollow floors do not absorb moisture into the building structure. Compared to Access Floors, they offer the advantage of an almost unrestricted choice of covering with less flexibility thanks to their seamless surface. The 600 x 600 mm panels are bonded together on their flanks using a special toothed groove to make them extremely rigid. Our hollow floor range includes 2-layer systems with point load-bearing capacities of up to 25 kN for showrooms, laboratories or production areas, lightweight systems made of wood-based materials, non-combustible systems, e.g. for office areas with additional functions such as displacement ventilation/room acoustics improvement/underfloor heating and cooling (also up to 20 kN point load-bearing capacity).

Additional services such as access floor ducts, inspection openings, sound and fire insulation, etc. complete our product range.

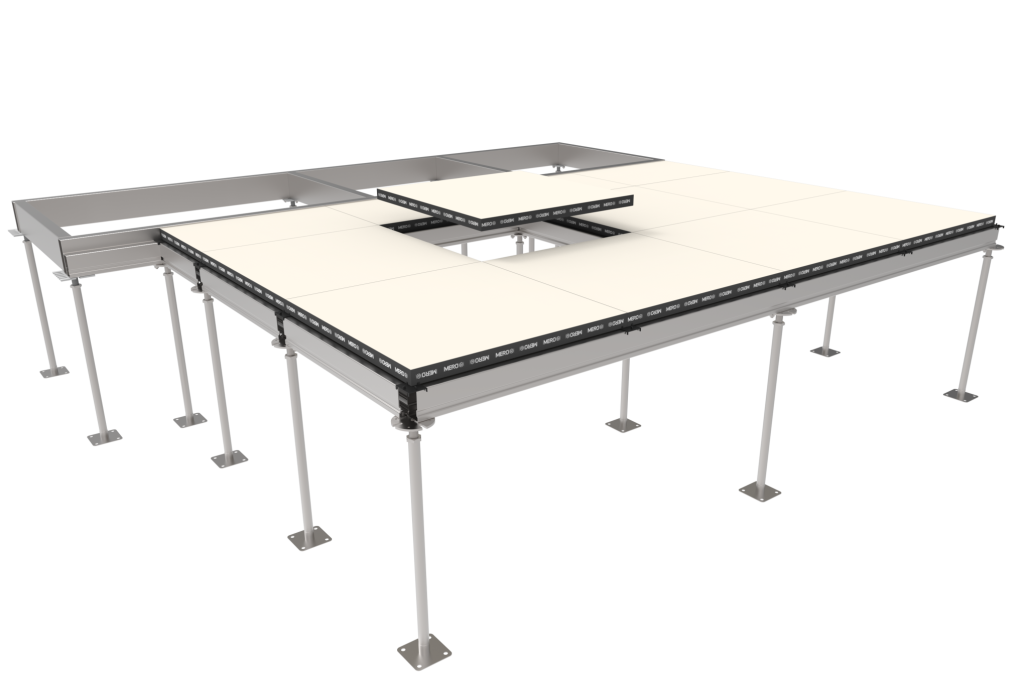

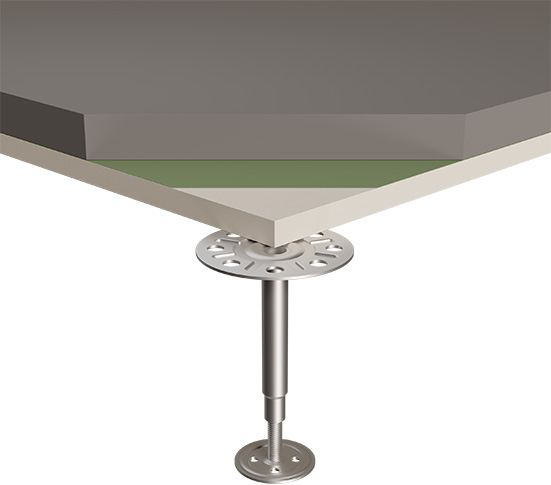

Combi T - Calcium sulphate hollow floor

Area of application: mainly in offices, laboratories, showrooms or reception halls

The Combi T dry hollow floor system is mainly used in offices, laboratories, showrooms or reception halls. The 28 – 80 mm thick base layer consists of calcium sulphate or gypsum fiber boards. In single-layer systems, the panels are bonded together on site in a 600 x 600 mm grid using a low-emission PU adhesive and glued to pedestals, creating a flat substrate for a variety of floor coverings. Height offsets are minimized by precise tooth milling at the edges. In two-layer systems, a second layer is also applied to the first layer in an adhesive bed. These systems are mainly used in foyer areas of office and administration buildings to accommodate, for example, cherry pickers or scissor lifts, in production areas of, for example, pharmaceutical companies, and generally in areas where heavy loads are transported or set up. Two-layer systems are suitable for supporting sensitive, rigid top coverings due to their low deflection. The load-bearing capacity is between 2,000 and 25,000 N in accordance with DIN EN 13213. The systems can be protected against moisture ingress by means of a steel or aluminum thin sheet lamination.

Combi T – Calcium sulphate hollow floor single layer 28-36 mm up to 10,000 N point load capacity according to DIN EN 13213 Combi T – Calcium sulphate hollow floor double layer 38/18 – 40/40 mm up to 25,000 N point load capacity according to DIN EN 13213

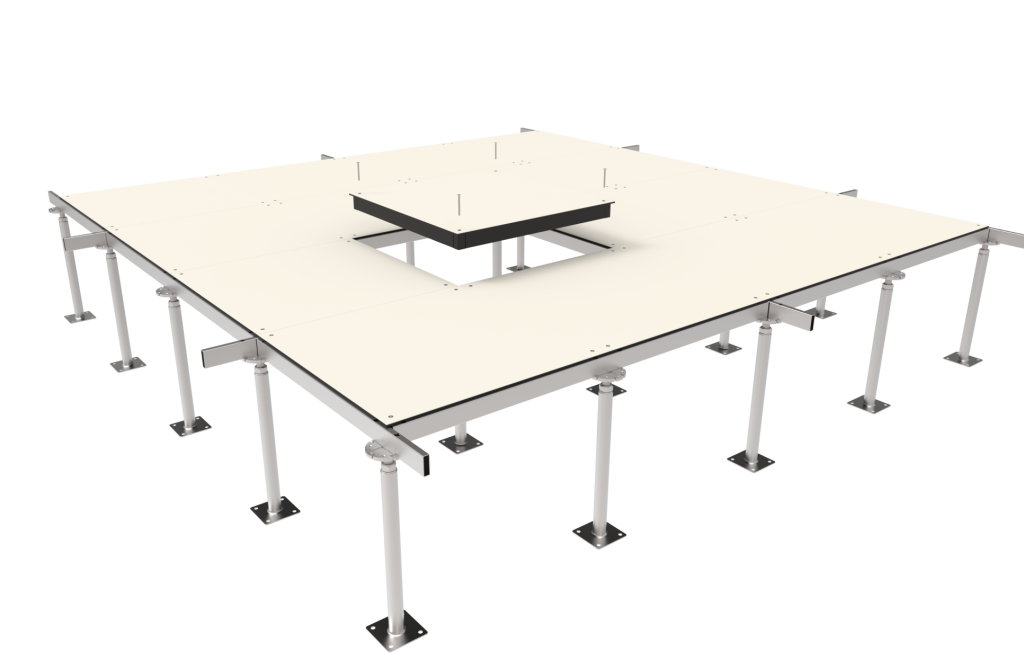

Combi T SPV - Wood-based hollow flooring

Area of application: mainly in offices

The Combi T – SPV dry hollow floor system is mainly used in offices. The base layer consists of a 30 or 38 mm thick, highly compressed wood-based panel. The panels are joined together on site in a 600 x 600mm grid using a low-emission PU adhesive and glued to pedestals, creating a flat subfloor for a variety of floor coverings. Height offsets are minimized by precise tooth milling at the edges. An aluminum thin sheet lamination protects the systems from moisture ingress on the top and bottom as standard. The point load-bearing capacity is 2,000 or 3,000 N in accordance with DIN EN 13213.

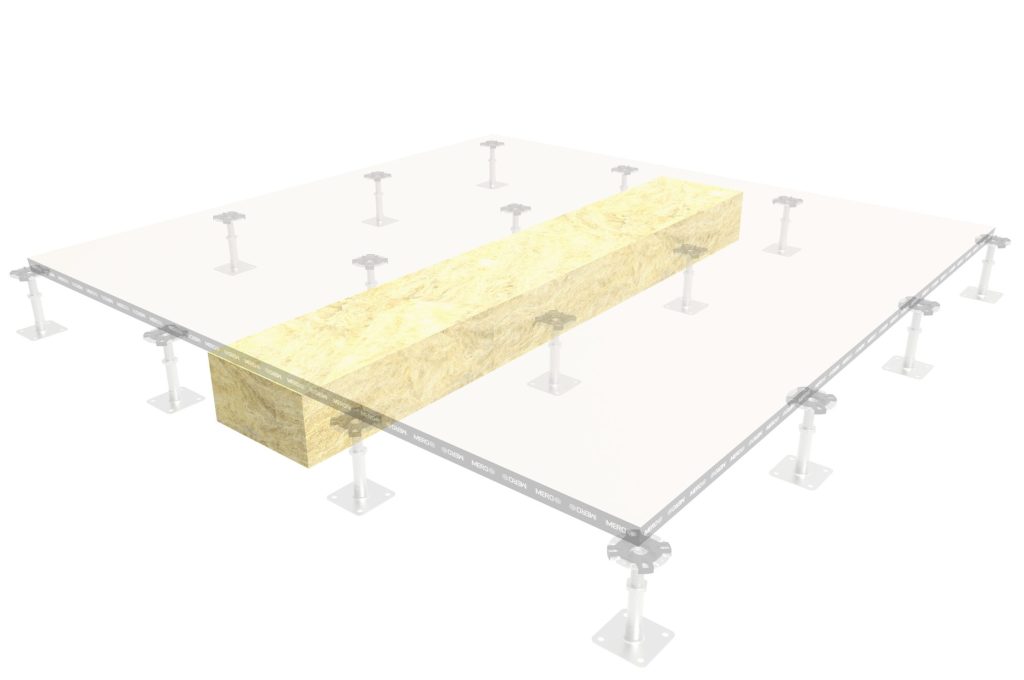

Combi T Thermo - calcium sulphate hollow floor with heating/cooling function

The Combi T Thermo hollow floor system adds a heating and cooling function to the basic CombiT system. Grooves are milled into the 40 mm thick calcium sulphate panels at the factory to accommodate the Ø14 mm heating pipes at intervals of either 100 or 150 mm. In order to create a flat surface for the surface covering and to guarantee the specified heating and cooling capacities, the groove is then filled with a cementitious filler and smoothed. The heating circuit is usually calculated by MERO-TSK. The interface to the heating contractor is the heating circuit manifold provided by the customer. The pipes, which are pressurized with air by MERO-TSK, are then laid by the heating engineer. The system is DIN Certco certified. These systems are mainly used in foyer areas of office and administration buildings to accommodate, for example, cherry pickers or scissor lifts, in production areas of, for example, pharmaceutical companies, and generally in areas where heavy loads are transported or set up.

Depending on the installation distance and flow and return temperatures, heating outputs of up to approx. 89 W/m2 and cooling outputs of up to approx. 38 W/m2 can be achieved in accordance with DIN EN 1264-2 and -5.

The point load-bearing capacity is 3,000 – 5,000 N for a single-layer structure and up to 20,000 N for a double-layer structure in accordance with DIN EN 13213.

Combi T Silent - calcium sulphate hollow floor with room acoustics function

The Combi T Silent system works like an acoustic ceiling system at floor level. The perforated calcium sulphate panels absorb sound energy – similar to an acoustic ceiling – especially at low frequencies, thereby reducing reverberation and ensuring pleasant acoustics in the room. With a free cross-section of 10.5% to 26%, for example, with a Vebe Strong 956 quality needle felt sheet and an acoustic fleece applied to the underside, a weighted sound absorption coefficient αw of 0.50 (LH) to 0.70 (LH) is achieved. These systems are mainly used in foyer areas of office and administration buildings to accommodate, for example, cherry pickers or scissor lifts, in production areas of, for example, pharmaceutical companies, and generally in areas where heavy loads are transported or set up.

The point load-bearing capacity is 3,000 – 6,000 N according to DIN EN 13213, depending on the free cross-section and load-reinforcing measures.

Floor systems

Dry hollow floor - Accessories

Openings for device inserts

Openings for device inserts can be drilled in the factory or subsequently on site. Standard dimensions for round openings are Ø305 mm or Ø215 mm. Angular cut-outs or stepped drill holes are also possible. Additional supports can be fitted as required. The device inserts are usually installed by the TGA trade after the top layer has been laid.

Fire bulkhead

Raised floor channel

Raised floor trunking consists of raised floor panels arranged in one or more rows. They allow convenient access to power or data cables in the floor cavity, for example. The transition to the hollow floor can be designed with or without an aluminum profile. In the case of permanently applied coverings, this profile can be fitted with a height-adjustable covering separator strip.

Inspection opening

Inspection openings consist of one or a maximum of two raised access floor panels. They allow partial access to the floor cavity. The transition to the hollow floor can be designed with or without an aluminum profile. In the case of permanently applied coverings, this profile can be fitted with a height-adjustable covering separator strip.

Separating cut for sound decoupling

Front cladding

Ramp

Project reports

Reference projects

Contact us

Questions on this topic?

Find a contact person

Your direct contact at MERO-TSK is:

Your contact from the premium partner network:

Gintaré Nariúnaité

H. Schowert Modern floor technology, Warstein

Laskowski Systemboden GmbH, Feldkirchen

Thomas Grössing

Responsibility: Vienna, Burgenland, Lower Austria – Postal code 2